Машиналар әртүрлі материалдарды сұрыптау және тегіндеу кезінде маңызды rol атқарады және оларды екі негізгі түрге бөлуге болады: айналымды және шытырған экран. Олар бір-бірімен ұқсас дегенімізде, олар арасында маңызды айырмашылық бар. Бұл машиналар Шанхай қаласында орналасқан Шанхай Юаньюда компаниясының құрылатын. Енді айналымды экран мен шытырған экран қандай себептерге сәйкес топтастырылған немесе орналасқанын талдау уақыты келді!

Айналымды Экран қандай? Шытырған Экранмен қатар, қандай айырмашылықтар және ұқсамалар бар?

Айналымды және шытырған экранлардың ішкі қызметкерлері арқылы да айырмашылық бар. Айналымды экранлар Феррис айнасына (Феррис wheel) ұқсас айналымды әрекет етіп, материалдарды экрандың астына басып отырады. Сонымен қатар, шытырған экранлар артқа және алға қозғалады, сондай-ақ неғұрлымын шытырған әрекет етеді. Шанхай Юаньюда компаниясының шытырғушы әрекетінің амплитудасы. гранулатор-құрылғы материалдың поверхностьын конвейер сияқтығына айналдырады. Бұл үлкен көлемді материалдар үшін және көп материал тегістері керек болатын жағдайда айналулы экранға дағдылар береді. Мүмкін, бір тәртіпте, кіші шамалы материалдармен жұмыс істей отырған жағдайда, жеңілдесетін экрандар тиімдірек және пайда болмаған ұпаймен класификация үшін ең қажетті.

Айналулы және Жеңілдесетін Тегістер Арасында Салыстыру

Айдағы ротациялық және сіңірлеу классификаторларының іс-әрекет механизмі туралы талқыланған, енді олар арасындағы айырмашылықтарды келесілерде білу үшін қараңыз. Ротациялық классификаторлар қаңша немесе құрт сияқты құттық материалдар үшін табысыз пайдаланылады. Бұл құттық материалдарды жылдам сорту керек отырып (мысалы, қоғамdar немесе маңай индустриялары) оларды идеалды ретте қояды. Ал сіңірлеу классификаторлары құттық материалдармен, мұндағы қорық немесе суық шыртымен пайдаланылады, сіңірлеу классификаторлары туралы көбірек мәліметтер төмендегілерде берілген. Егер де материалдарды сорту қажет болса, тоқырлар әдетте жақсы таңдауға мүмкіндік береді, себебі олардың іс-әрекеті қырқындау принципіне негізделеді.

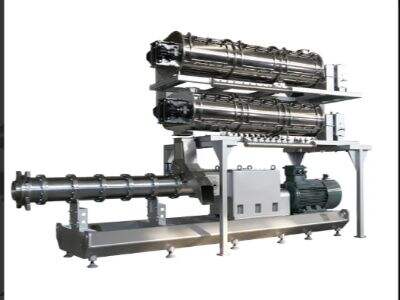

Төртінші айырмашылық әлде өндірістің үлкен өлшемі мен нисанға қарағанда төменгі құнында. Айналуық салынушылар бас тартылып, вибрациялық салынушыларға салыстырғанда үлкен және әлдеқайда қымбат. Бірақ, салыну қуанышының жоғары дәрежедегі дәлдігі талап етілген кезде, ол вибрациялық салынушылардың алдын алуына болады. Сонда да, олардың дәлдігін қосып отырып, бірнеше сегменттерде, мазмұнда, ас қойымдарында маңызды деп анықталды. Ас қойымдарын өңдеуде, материалдар қауіпсізлік пен ас қызметкерлігі үшін танымал өлшемдерге бөлу керек. Сондықтан, тяжелая жұмыс іс-әрекеті үшін Шанхай Юаньюда extruder-equipment бұл жұмысқа қатысты ең қажеттілер, ал әлдеқайда тәсілік жұмыстар үшін вакуумдық және вибрациялық салынушылар қажет.

Айналуық және вибрациялық экрандарды өндірістерде қолдануға қатысты плюслері мен минустері бар, олар төмендегідей талқыланады.

Келесіңіз, біз әр түрлі экран түрлерінің плюслері мен минустерін қарастырамыз. Айналымды экрандар келесі плюстарға ие: Бұл, бір уақытта өте көп материалды оброботка ету мүмкіндігінде да анықталады, сондықтан ұзақ кезектегі жұмыс үшін маңызды болады. Олар вибрациялық экрандарға салыстырғанда әдетте жоғары күшке ие болып, қатынасқа байланысты жұмыс істейтін жағдайлarda әдетте ұзақ қызмет күтімі бар. Бірақ, олармен қосымша мәселелер - әдетте құны қатынасыnda бірнеше артық және олар әдетте құтқаруға дейінгі, сондықтан да көптеген кеңес беру керек.

Бір тақырыпта, көлемдік экранлар келесі жадвалда көрсетілгендей мәндерді жетілдіруге мүмкіндік береді; Бұлар ротациондық экрандарға салыстыrsa да, әдетте арзан болып, кем даму керек. Бірақ, ол ротациондық экрандар сияқты қалыпты емес, бірақ ұзақ уақыт қолданылатында жылдам созылуы мүмкін. Оның іс-шарыасына қатысты материалдың мөлшеріне байланысты әлдеқайда тез әрекет етеді, сонымен қатар, ол әлдеқайда дәлдік талап ететін қолданбалarda қолданылады.

Мынадай естелер кейінгі операциялар үшін ротациондық және көлемдік класификаторлар арқылы өткізіледі.

Иimdi осы класстерлерді және оларды ішкі түрде қалай есептейтіні туралы қарастырайық. Ротациондық класстерлердің функционалдық жұмыс әдісі: Экран айналғанда, материалдар кіші шаршылар арқылы түседі. Көлік материал экранның жоғары жағында қалады және бір уақытта экранның соңынан шығарылады, ал жеміс материал экранның ішінен өтуге дейін уақыт қажет етеді. Белгілі тәсіл сиқырлау операциясы үшін пайдалы екен.

Бірақ, салыстыру класстерлері экраны салыстыратын әдісті қолданады. Салыстыру әрекеті материалдарды экранда сұрыптау арқылы өлшемдері бойынша салыстырады. Ескерту қажет, экрандағы шаршылар бұл процедураның маңызды элементі. Шаршылар материалдардың қандай өлшемде өтуі мүмкін екенін анықтайды. Сонымен қатар, шаршылар кіші болса, материалдардың салыстырылуы көп отрасльдер үшін әлдеқайда дәл болады.

Класстерлеу Экрандары: Дұрыс Тандаудың Құралы

Бұл түрдегі салыстыру экранын таңдағанда келесілерді қарастыру маңызды. Бұл түрлі концепцияны қолдану үшін, бірінші ретте, нені бөлу керек екенін қарастырыңыз. Оның құттығы немесе суы бар ма? Екіншісі, сорту үшін келесі мәліметтердің көлемін қарастырыңыз. Ол қанша? Көп екенімде немесе аз? Соңғысымен, сорттау үшін қажетті дәрежені қарастырыңыз. Негізгі түрде, Шанхаи Yuanyuda. grinding-equipment жамбылдық материалдардың үлкен көлемімен жұмыс істей отырмын болса, ол ең жақсы және ең praktikalyқ шешім болуы мүмкін. Бірақ, егер сіз ыстық продуктарды дәл салыстыру керек болса, онда вибрациялық салыстырушы сіздің талаптарыңызға қанағаттандыратын ең қарайымды шешім болады.

Әрбір жағдайда, ротациондық синтезаторлар мен салындырушы синтезаторлармен бірге, олар арасында бірдей ұқсамалық болуы мүмкін, бірақ оның анықталуы керек, екі жолы да түрлі негізде қалаған және бұл айырмашылықты жасайды. Осы айырмашылықтарды түсіну сізге қандай экран түрі сізге ең жақсы келетіні таңдауда дұрыс шешім қабылдауға мүмкіндік береді. Шанхай Юаньюда компаниясы материалдарды бөлу және синтезациялау үшін ротациондық және салындырушы синтезаторларда әлемдегі жетістіктерге ие. Егер сізде сұрақтар болса немесе қажетті продукт пен шешімді таңдауда көмектің керек болса, ізденуге тырысыңыз!

Мазмұны

- Айналымды Экран қандай? Шытырған Экранмен қатар, қандай айырмашылықтар және ұқсамалар бар?

- Айналулы және Жеңілдесетін Тегістер Арасында Салыстыру

- Айналуық және вибрациялық экрандарды өндірістерде қолдануға қатысты плюслері мен минустері бар, олар төмендегідей талқыланады.

- Класстерлеу Экрандары: Дұрыс Тандаудың Құралы

EN

EN